Multifunction Printers

Cut Sheet Printers for High-Volume Business Printing

High-volume teams want speed, color accuracy, and reliability without ballooning costs, which is why cut sheet printers remain the backbone of modern production floors that run tight deadlines every day. Gulf Coast Office Products ensures that commercial buyers can compare options, clarify must-have specs, and map equipment decisions to real workloads. Your organization can trust our stellar team as a means to invest in color cut sheet printers and related commercial printing equipment with confidence.

- 10.1" Smart Operation Panel

- Mobile Printing

- PostScript3 Emulation

- 500-Sheet Paper Tray

- 10.1" Smart Operation Panel

- 50-Sheet Single-Pass Document Feeder

- 550-Sheet Paper Tray

- 100-Sheet Bypass Tray

- 4.3" Touch Panel

- 250-Sheet Paper Tray

- 1-Sheet Bypass Tray

- 50-Sheet Single Pass Document Feeder

- 4.3" Color Touch Panel

- 250-Sheet Paper Tray

- 35-Sheet Automatic Reversing Document Feeder

- 50-Sheet Bypass Tray

- 2.8" Touch Panel

- 250-Sheet Paper Tray

- 1-Sheet Bypass Tray

- 50-Sheet Automatic Document Feeder

- 10.1" Smart Operation Panel

- Mobile Printing

- PostScript3 Emulation

- 500-Sheet Paper Tray

- 10.1" Smart Operation Panel

- Mobile Printing

- PostScript3 Emulation

- 500-Sheet Paper Tray

- 10.1" Smart Operation Panel

- Mobile Printing

- PostScript3 Emulation

- 500-Sheet Paper Tray

- 10.1" Keyless Smart Operation Panel

- 220-Sheet Single Pass Document Feeder

- Automatic Duplex

- PostScript3 Emulation

Why Cut Sheet Still Dominates Modern Production

Operations leaders choose cut sheet platforms because they balance speed with flexibility, handling everyday work as well as premium jobs without complex changeovers. These devices accept a wide range of paper types, weights, and sizes, which simplifies job planning and reduces waste tied to mismatched substrates. Teams also appreciate that cut sheet printers scale easily from departmental use to full production environments, which preserves capital while the shop grows.

What Counts as a Production Printer in Louisiana?

Production printers in Louisiana serve organizations that need monthly volumes measured in the hundreds of thousands, consistent color management, and automated finishing. Buyers in manufacturing, healthcare, education, and municipal offices often rely on these systems to deliver transactional print, marketing collateral, and compliance documents with absolute predictability. Local service matters as much as headline speed, since uptime depends on fast parts access and technicians who know your workflow.

A true production device offers duty cycles that comfortably exceed your planned volumes, which prevents running at the ragged edge and improves longevity. Robust engines, high-capacity input trays, and smart job scheduling combine to keep queues moving during peak periods, which means deadlines get met without overtime. Color cut sheet printers add calibrated profiles and tight registration so that every run looks consistent across shifts, operators, and paper lots.

Color Cut Sheet Printers vs. Black and White: Which Delivers More Value?

Marketing-led organizations typically favor color cut sheet printers because brand fidelity, photo-heavy layouts, and variable data pieces gain measurable lift from accurate color. Sales teams report higher response rates when color contrast, image sharpness, and coating options align with campaign goals, which turns quality into revenue instead of overhead. Print rooms that handle catalogs, mailers, and signage often place color first, then supplement with monochrome for internal packets and forms.

Monochrome production still shines where clarity and cost per page drive decisions, such as statements, manuals, and records. A blended fleet can unlock the best of both worlds by routing work intelligently, which keeps premium color devices focused on revenue work while black-and-white units shoulder routine runs. This approach lowers cost per impression without sacrificing turnaround or consistency.

How Fast Is Fast Enough for Your Volumes?

Speed numbers on a spec sheet only tell part of the story because real throughput depends on file types, RIP performance, and finishing steps. Shops that run complex variable data, heavy coverage, or textured stocks should evaluate rated speeds alongside controller power and job management tools. Careful matching prevents bottlenecks at the digital front end, which protects cycle time from prepress to finished box.

Essential Features That Protect Your ROI

High duty cycle headroom that keeps daily loads well below the engine ceiling, which extends component life and stabilizes quality.

Advanced media handling for coated, synthetic, and heavyweight stocks, which opens profitable applications without outsourcing.

Automated calibration and color management that maintain accuracy between runs, which reduces reprints and saves toner.

Inline finishing such as stapling, punching, folding, and booklet making, which shortens turnaround and frees staff for higher-value tasks.

Secure print, user authentication, and audit trails, which keep sensitive content controlled in regulated environments.

Service diagnostics with predictive alerts, which help schedule maintenance around deadlines and minimize surprise downtime.

A Simple Way To Choose the Right Cut Sheet Platform

Tally average and peak monthly impressions, then target a device with duty cycle headroom of at least fifty percent to safeguard uptime.

List paper sizes, weights, and specialty stocks, then confirm feed paths and fuser tolerances that match those applications.

Specify delta-E targets, calibration routines, and proofing needs so color cut sheet printers meet brand standards without manual tweaks.

Combine acquisition, service, consumables, and labor to evaluate cost per finished piece rather than cost per click alone.

Run your heaviest files through the controller, observe queue behavior under load, and measure true end-to-end throughput with finishing.

Verify technician coverage, parts availability, and remote diagnostics that reduce mean time to repair and keep production printers in Louisiana online.

Industries That Rely on Commercial Printing Equipment

Healthcare systems that generate intake packets, discharge instructions, and outreach mailers on tight timetables.

Universities and districts that need course packs, recruitment pieces, and event materials across multiple campuses.

Financial and municipal offices that produce statements, notices, and election materials with strict accuracy requirements.

Retail, hospitality, and tourism brands that refresh menus, signage, brochures, and seasonal campaigns at high frequency.

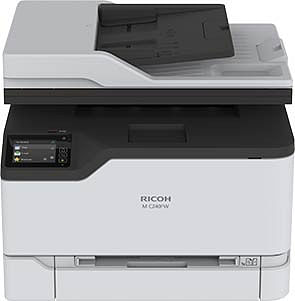

Compare Ricoh Models Side by Side

Decision makers evaluating Ricoh color cut sheet printers can expect robust engines, intuitive interfaces, and controllers that handle heavy graphics with ease. A side-by-side comparison clarifies differences in rated volumes, media ranges, and finishing options, which makes it simple to match a platform to print room goals. GCOP helps teams review sample output, validate substrates, and verify finishing sequences so that the chosen device delivers day one.

Total Cost of Ownership That Stays Predictable

Budgets benefit when devices run within their comfort zone, supplies are forecasted accurately, and finishing happens inline rather than offsite. Accurate cost modeling includes throughput, reprint rates, and labor minutes saved by automation, which often reveals that premium engines pay for themselves through fewer touches. GCOP provides clear service terms and consumption data so that finance teams know exactly what to expect each month.

Build Capacity With Color Cut Sheet Printers

Growth plans become achievable when your print room can accept more work without sacrificing quality or deadlines. Whether you operate an in-plant serving internal departments or a commercial shop competing for regional accounts, the right cut sheet printers elevate output, control costs, and win repeat business. Production printers in Louisiana sourced and supported locally give you an immediate edge in responsiveness.

Why GCOP Is the Local Leader for Production Printers in Louisiana

Commercial buyers choose GCOP because the team pairs deep product knowledge with a consultative approach that prioritizes business outcomes over model numbers. Site assessments, workflow mapping, and sample runs ensure each recommendation fits your floor space, network, and operator skill set before any commitment. The result is a solution built around your real jobs, not a generic catalog page.

Organizations also value GCOP’s lifecycle support, which includes installation, color profiling, and operator training delivered by experienced specialists. Service agreements emphasize rapid response, genuine parts, and proactive maintenance, which protects throughput during your busiest seasons. This focus on uptime converts into predictable schedules, happier clients, and healthier margins.

Deployment, Training, and Ongoing Support

Smooth rollouts start with careful staging, network integration, and acceptance testing that catches issues before the first production shift. Color targets, queues, and permission sets get configured in partnership with your operators, which builds confidence and reduces early disruptions. Clear documentation and quick-reference guides support new hires and cross-training without adding managerial burden.

Ongoing support keeps performance consistent as job mixes evolve, paper vendors change, and new campaigns introduce different coverage patterns. Preventive maintenance windows get aligned with your calendar, firmware updates are planned, and parts are stocked strategically to shorten repair cycles. This disciplined approach treats commercial printing equipment as a production asset that deserves the same rigor applied to any revenue-critical machine.

Ready To Print Smarter With Cut Sheet?

Your next project deserves a platform that delivers speed, accuracy, and reliability across every shift, which is exactly what our recommended color cut sheet printers provide. GCOP will help you compare options, run samples, and finalize a support plan that keeps your schedule tight and your costs controlled. Choose GCOP for the best cut sheet printer services around, and transform your print operation into a faster, more profitable part of the business.